Today, it is announced that its new series of high-performance grinding products have been officially put into the market, aiming at meeting the growing demand for high-efficiency, precision and durable abrasives in industries such as industrial manufacturing, metal processing, automobile maintenance and construction. The core products launched this time include innovative Ceramic Strip Disc, Ceramic Abrasives Flap Disc and classic Brown Fused Alumina Flap Disc. Product highlights and technical advantages

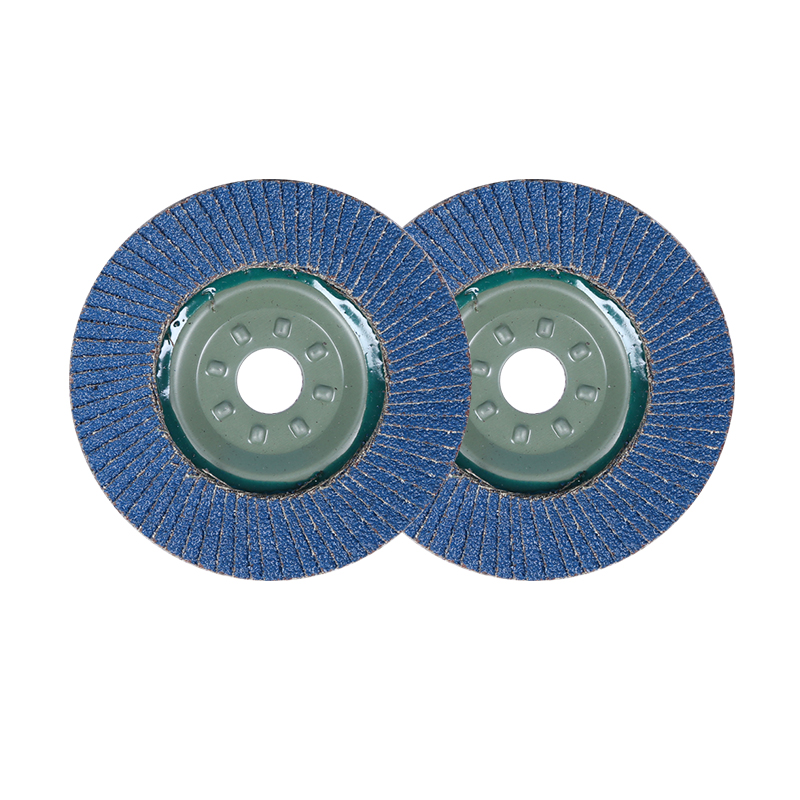

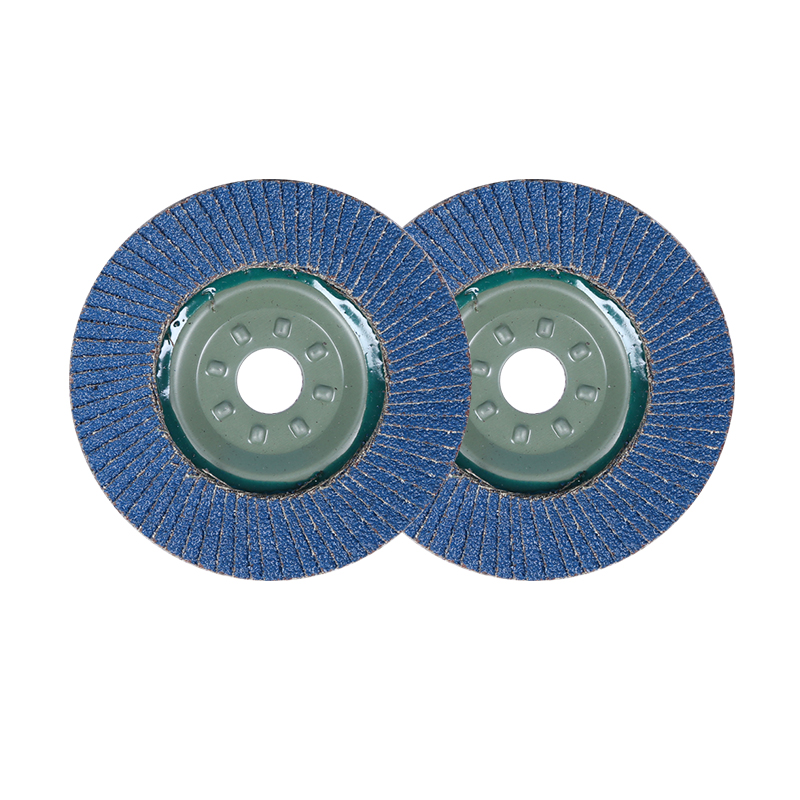

1. Ceramic Strip Disc: Cutting-edge ceramic abrasive technology: advanced ceramic alumina abrasive is adopted, and its unique self-sharpening crystal structure can be continuously broken to form a new sharp cutting edge during grinding. Extraordinary grinding efficiency and service life: Compared with traditional zirconia corundum or brown corundum grinding wheels, ceramic grinding wheels can improve the efficiency by as much as 30%-50% and prolong the service life by 2-3 times when grinding hard and hard-to-grind materials such as stainless steel, alloy steel and titanium alloy, and significantly reduce the single grinding cost and replacement frequency. Cold cutting reduces burns: the heat generated in the grinding process is lower, which effectively reduces the risk of burns on the workpiece surface, protects the material properties and improves the processing quality. Better surface finish: provide smoother and more consistent grinding effect, and reduce subsequent finishing procedures. Application: It is widely used in stainless steel welding seam cleaning, groove processing, flash burr removal, surface finishing and other demanding operations. 2. Ceramic Abrasives Flap disc: Perfect combination of ceramic abrasive and fiber substrate: high-performance ceramic abrasive is applied to flexible fiber cloth substrate, combined with precise arrangement of sand petals design. Excellent grinding force and flexibility: ceramic abrasive provides powerful cutting force, and the flexibility of fiber substrate enables it to perfectly fit complex surfaces, achieving dual effects of efficient grinding and fine polishing. Fast heat dissipation, not easy to block: the unique structural design is beneficial to heat dissipation, reducing the thermal deformation of the workpiece, and effectively resisting the adhesion and blocking of soft metals (such as aluminum). More comfortable operation and finer surface: less grinding vibration and easier operation; It can realize seamless connection from rough grinding to fine grinding (partial particle size), and obtain more uniform and finer surface treatment effect. Application: It is especially suitable for metal grinding, weld finishing, fillet, mold trimming, automobile body repair and so on, which require high surface quality. 3. Brown Fused Alumina Flap Disc: Economical and efficient universal choice: high-quality brown corundum abrasive is used, which has good toughness and versatility. Wide applicability: it has good grinding effect on carbon steel, cast iron, common alloy steel, wood and other materials. Outstanding cost performance provides stable, reliable and economical solutions in conventional grinding, rust removal, paint removal, chamfering and other applications. Application fields: Basic grinding needs in daily metal processing, equipment maintenance, construction sites, carpentry and other fields.

About the company

Shandong Guanchang New Material Co., Ltd. is a factory specializing in the production of hundred impellers. The factory covers an area of 10,000 square meters and is located in Dadian Industrial Park, Linyi City, Shandong Province, the hometown of abrasive tools in China. The factory is about 50 kilometers away from Linyi Airport and 200 kilometers away from Qingdao Wharf Port, with convenient transportation by land and sea.